China’s business relationship with Africa and South Africa is strengthening with every passing day. But while South African business enjoys the prospects of investment from the east, it may have overlooked some reciprocal investments that can be made in the world’s newly second largest economy.

China’s business relationship with Africa and South Africa is strengthening with every passing day. But while South African business enjoys the prospects of investment from the east, it may have overlooked some reciprocal investments that can be made in the world’s newly second largest economy.

This month’s SmartProcurement considers the benefits of China’s warehousing options, as presented in a report by C.H. Robinson Worldwide.

“China continues to be a supply chain hotspot for many organisations who want to expand their global business operations. A key reason for this growth is that China continues to be a vital supply point and economic hub of global commerce, with business volumes on a steady incline. As a result, the country is improving and expanding infrastructure, diversifying and amplifying supply chain service offerings, and implementing new customs policies to better accommodate the organisations making this shift,” says the report.

“In particular, China’s warehouse solutions are appealing because they allow companies to consolidate orders from multiple vendors and ship directly to end customers, bypassing more costly distribution networks in other regions of the world, such as North America and Europe. And since a large majority of companies are already doing some kind of business in or with China, pursuing a warehouse solution in China can be a logical next step.

How warehousing works in China

Organisations that manufacture goods in China must be registered to either produce for export or for domestic consumption, says the report. In order to gain domestic distribution rights in China, they must operate legally within the Wholly Foreign Owned Enterprise (WFOE) framework, which is growing increasingly easier due to the relaxation of government regulations made possible as China entered the World Trade Organization (WTO). Once an organisation has met the legal requirements to manufacture in and distribute from China, the next step is choosing the right programme and type of warehouse.

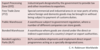

The report discusses the guises under which Chinese warehouse consolidation programmes fall. There are single importer / multiple vendor consolidation programmes, multiple importer / multiple vendor consolidation programmes, and direct import programmes, which are not specifically built around consolidation, but more about shipping product directly from origin to end customers.

These models are ideal for vendors located in the same country as the warehouse. If your vendors are located in a different country than your warehouse, these options could have a reverse effect and cause transportation costs to increase.

Within these programmes, there are many different types of warehouse options organisations can use to consolidate orders. The options are many and will vary for different industries, commodities and market channels. In each type of warehouse, the balance of inventory, warehousing, customer service, and freight costs will be different and determined by the characteristics of the commodity and the demand.

Within these programmes, there are many different types of warehouse options organisations can use to consolidate orders. The options are many and will vary for different industries, commodities and market channels. In each type of warehouse, the balance of inventory, warehousing, customer service, and freight costs will be different and determined by the characteristics of the commodity and the demand.

Depending on the type of warehouse solution an organisation desires, it must perform due diligence and carefully consider each programme and type of warehouse to ensure it selects the solution that best aligns with its global supply chain strategies and goals.

Exploring the benefits

While pursuing warehouse opportunities in China helps organisations streamline their global supply chains, improve efficiencies, and reduce costs, there are many additional benefits, says the report.

A well-executed and managed warehouse solution in China can help organisations:

• Distribute their product directly from China to end customers and avoid more expensive distribution networks, such as North America or Europe.

• Choose from multiple warehouse options owed to more flexible customs policies in China.

• Gain transparency over end-to-end supply chain spending and reduce transportation costs.

• Improve cash flow.

• Gain extended visibility for earlier decision-making, risk prevention, and security control.

• Maintain control over shipments post-production.

• Relieve pressure on the destination’s distribution network.

• Improve vendor management and compliance.

• Pursue new sales and branding opportunities in other global markets.

“[Organisations] that do rise to the next management level by integrating their export-oriented activities for global markets with their domestic market operations are achieving higher levels of profitability…[Organisations] that successfully integrate their China operations enjoy profitability of 29.6 percent, on average, compared with 17.8 percent profitability for those that do not,” said a Booz Allen Hamilton report China’s Shifting Competitive Equation: How Multinational Manufacturers Must Respond.

In next month’s SmartProcurement we’ll discuss the potential challenges of warehousing in China.